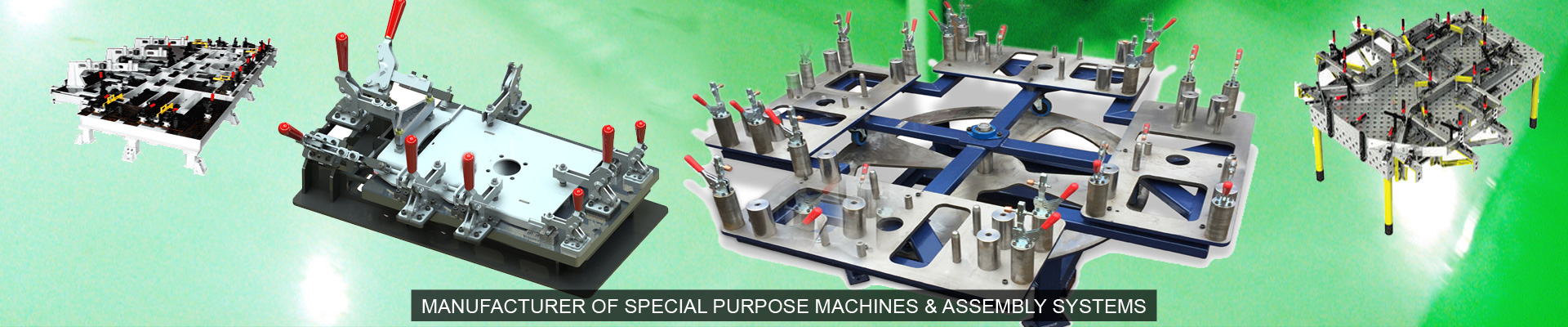

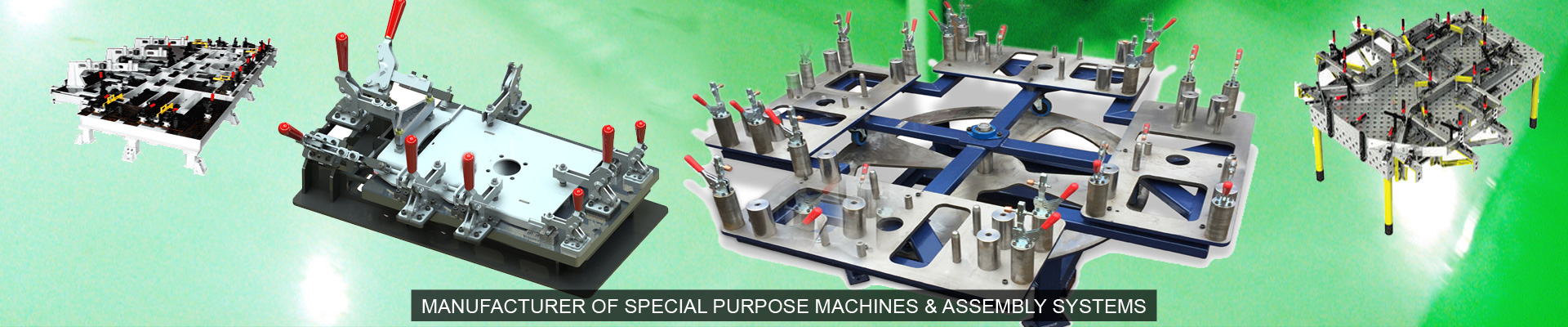

JIGS AND FIXTURES

-

Jigs:

A jig's primary purpose is to provide repeatability, accuracy, and interchange ability in the manufacturing of products. A jig is often confused with a fixture; a fixture holds the work in a fixed location. A device that does both functions (holding the work and guiding a tool) is called a jig.

The jig is used for guiding the cutting tools (like a drill bit), and for doing so, jigs have components like a bush, which encounters the cutting tool.

Fixtures:

Fixtures are the work holding device, which holds, supports, and locates the work piece but not guides the cutting tool to perform a specific operation. The main purpose of the fixtures is to hold and locate the work piece.

Advantages of Jigs and fixtures:

• It eliminates the setting time required before machining.

• It increases the machining accuracy and increases production capacity.

• Requires less skilled operation.

• They reduce the production cost.

• Increases machine and labour utilization.

• They simplify the work handling.

• Increases the quality of production in the industry.

• They enable the quick setting of a tool and the proper positioning of the work.

Applications of Jigs and Fixtures:

• Inspection of parts in continuous production in manufacturing industries.

• Mass production of automobile parts.

• For drilling the flanges and drilling holes to any required angles.

• Jigs used for mass drilling, reaming, and tapping.

• Fixtures used for milling, mass turning, and grinding operations.

All rights reserved.